Page 185 - CW E-Magazine (22-10-2024)

P. 185

Special Report Special Report

Table 4: Chemicals used in TFT fi cant strides in reducing its environ- Furthermore, the integration of

Type Materials & chemicals mental impact by decreasing the use PV systems with advanced energy

Basic materials Gallium arsenide (GaAs), cadmium tellu- of toxic materials like cadmium and storage technologies, like solid-state

batteries, is a key area of innovation

lead, although challenges remain, par-

ride (CdTe), copper-indium-gallium selenite ticularly with regard to recycling and that could enhance the overall effi -

(CIGS), amorphous silicon. disposal. ciency and reliability of solar power

Speciality gases Argon, fl uorine, helium, hydrogen selenide, systems.

nitrogen trifl uoride. There has been progress in the

Bulk gases Hydrogen, nitrogen, oxygen. development of methods to recycle PV CONCLUSION

Silicon precursor gases Dichlorosilane, silane, silicon tetrachloride, materials, especially silicon and metals The PV industry and the chemical

trichlorosilane. used in contacts, to reduce waste and industry are highly interconnected,

Dopants Diborane, germane, phosphine, trimethyl promote sustainability. with the latter playing a vital role

at multiple stages of the PV supply

boron (all in hydrogen). Durability and stability chain. The supply chain begins with

Wet chemicals Cadmium sulphide coating systems, potas- One of the signifi cant challenges the extraction and processing of raw

sium cyanide etching system. with perovskite solar cells has been materials required for PV cell produc-

Metallisation Silver for grid and bus bar; solderable silver, their long-term stability. But over the tion and goes all the way through to

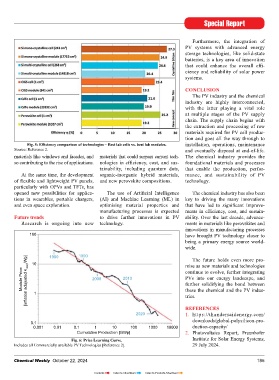

carbon electrode materials. last decade, innovations in encapsula- Fig. 5: Effi ciency comparison of technologies – Best lab cells vs. best lab modules. installation, operations, maintenance

Encapsulants Polyvinyl butyral. tion, material engineering, and device Source: Reference 2. and eventually disposal at end-of-life.

materials like windows and facades, and materials that could surpass current tech- The chemical industry provides the

Table 5: Chinese PV manufacturing by component and province so contributing to the rise of applications. nologies in effi ciency, cost, and sus- foundational materials and processes

tainability, including quantum dots, that enable the production, perfor-

Province Rank in China Polysilicon Ingots Wafers Cells Modules At the same time, the development organic-inorganic hybrid materials, mance, and sustainability of PV

1 Xinjiang Inner Mongolia Jiangsu Jiangsu Jiangsu of fl exible and lightweight PV panels, and new perovskite compositions. technology.

2 Inner Mongolia Yunnan Yunnan Zhejiang Zhejiang particularly with OPVs and TFTs, has

3 Jiangsu Ningxia Inner Mongolia Sichuan Anhui opened new possibilities for applica- The use of Artifi cial Intelligence The chemical industry has also been

4 Sichuan Jiangsu Jiangxi Shaanxi Hebei tions in wearables, portable chargers, (AI) and Machine Learning (ML) in key to driving the many innovations

optimising material properties and that have led to signifi cant improve-

and even space exploration.

5 Qinghai Sichuan Ningxia Henan Jiangxi manufacturing processes is expected ments in effi ciency, cost, and sustain-

Chinese fraction of global 72% 98% 97% 81% 77% Future trends to drive further innovations in PV ability. Over the last decade, advance-

capacity Research is ongoing into new technology. ments in materials like perovskites and

Top-5 Provinces fraction 93% 83% 81% 80% 84% innovations in manufacturing processes

of Chinese capacity 100 have brought PV technology closer to

Top-5 Provinces fraction 67% 81% 78% 65% 64% being a primary energy source world-

of global capacity wide.

Source: BloombergNEF 2021. 1980 1990 The future holds even more pro-

This distributes the light evenly, which traditional silicon cells in specific architecture have significantly 10 mise as new materials and technologies

makes the CPV modules more effi cient. applications. improved their lifespan. 2010 continue to evolve, further integrating

PVs into our energy landscape, and

Cost reduction The Experience Curve – also called Advances in encapsulation materi- Module Price [infl ation adujusted 2023 /Wp] 2000 further solidifying the bond between

Cost reductions have been driven Learning Curve – shows that in the last als and processes have also enhanced 1 these the chemical and the PV indus-

by innovations in material synthesis 43 years module prices decreased by the weather resistance of solar mo- tries.

and process improvements. For exam- 24.4% with each doubling of cumula- dules, in general, extending their opera-

ple, the cost of polysilicon production tive global module production. Cost re- tional life under harsh environmental REFERENCES

has decreased due to better production duction results from economies of scale conditions. 2020 1. https://thundersaidenergy.com/

technologies and economies of scale. and technological improvements. 0.1 downloads/global-polysilicon-pro-

Integration and applications 0.001 0.01 0.1 1 10 100 1000 10000 duction-capacity/

The commercial viability of TFTs Sustainability and environmental There has been substantial progress Cumulative Production [GWp] 2. Photovoltaics Report, Fraunhofer

like Cd-Te and CIGS has also im- impact in Building-Integrated PVs (BIPVs), i.e., Fig. 6: Price Learning Curve. Institute for Solar Energy Systems,

proved, making them competitive with The PVs industry has made signi- integrating solar cells into building Includes all Commercially available PV Technologies [Reference 2]. 29 July 2024.

184 Chemical Weekly October 22, 2024 Chemical Weekly October 22, 2024 185

Contents Index to Advertisers Index to Products Advertised