Page 172 - CW E-Magazine (29-7-2025)

P. 172

Special Report

displayed on the LCD display. The ducer propagates through diff erent Angle beam testing, as its name

only requirement for getting correct boundaries, with some of it refl ecting implies, is used to locate cracks and

results is to calibrate the instrument back to the receiver when a boundary discontinuities that are tilted to the

with a sample of known thickness, or an anomaly (such as a crack) is longitudinal axis of the pipeline. This

prepared from the same material encountered. The refl ected sound method is crucial because defects that

as that of the material of the pipe. wave is then converted to an electrical are not parallel to the surface are usu-

Figure-7 shows thickness monitoring signal by the transducer and shown on ally undetected by straight beam test-

of tubes and pipes by ultrasonic a display screen. In addition to fl aws, ing due to their orientation to the sound

gauge called ‘D-Meter’(3). ultrasonic testing can also reveal other wave. Such angled cracks and defects

crucial information, such as size, typically occur in welds and structural

While there are several methods orientation, thickness and other criti- metal components due undue stresses.

available for detecting cracking cal features (Figure-8). During this technique, a common

defects in pipelines, ultrasonic testing angle beam (wedge) transducer or

techniques are perhaps the most How is ultrasonic technology used an immersion transducer is angled at

efficient and user friendly. As such, during crack inspection? the appropriate inclination to emit the

this technology should form an inte- Ultrasonic testing of cracks in pipe- sound wave into the pipeline.

gral part of a pipeline asset owner’s lines is conducted using two methods:

quality control and management straight beam testing and angle beam Using advanced ultrasonic techno-

processes. testing. logies to further improve inspection

safety

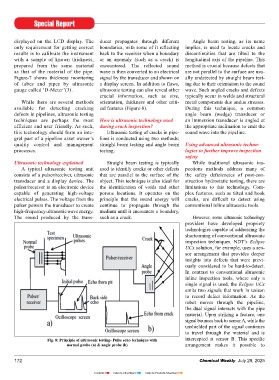

Ultrasonic technology explained Straight beam testing is typically While traditional ultrasonic ins-

A typical ultrasonic testing unit used to identify cracks or other defects pections methods address many of

consists of a pulser/receiver, ultrasonic that are parallel to the surface of the the safety defi ciencies of post-con-

transducer and a display device. The object. This technique is also ideal for struction hydrostatic testing, there are

pulser/receiver is an electronic device the identifi cation of voids and other limitations to this technology. Com-

capable of generating high-voltage porous locations. It operates on the plex features, such as tilted and hook

electrical pulses. The voltage from the principle that the sound energy will cracks, are diffi cult to detect using

pulser powers the transducer to create continue to propagate through the conventional inline ultrasonic tools.

high-frequency ultrasonic wave energy. medium until it encounters a boundary,

The sound produced by the trans- such as a crack. However, some ultrasonic technology

providers have developed propriety

technologies capable of addressing the

shortcoming of conventional ultrasonic

inspection techniques. NDT’s Eclipse

UCx solution, for example, uses a sen-

sor arrangement that provides deeper

insights into defects that were previ-

ously considered to be hard-to-detect.

In contrast to conventional ultrasonic

inline inspection tools, where only a

single signal is used, the Eclipse UCx

emits two signals that work in unison

to record defect information. As the

robot moves through the pipeline,

the dual signal interacts with the pipe

material. Upon striking a feature, one

signal bounces back to sensor A, while the

unshielded part of the signal continues

to travel through the material and is

Fig. 8: Principle of ultrasonic testing- Pulse echo technique with intercepted at sensor B. This specifi c

normal probe (a) & angle probe (b) arrangement makes it possible to

172 Chemical Weekly July 29, 2025

Contents Index to Advertisers Index to Products Advertised