Page 181 - CW E-Magazine (19-12-2023)

P. 181

Indian Petrochem 2023 Conference Indian Petrochem 2023 Conference

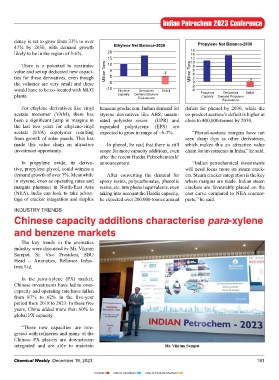

Signifi cant PE capacity additions are 2050, around 20% of olefi n production dency is set to grow from 33% to over Propylene Net Balance-2030

also forecast in the Middle East in 2025 would be through this route. 47% by 2030, with demand growth Ethylene Net Balance-2030

and 2026. likely to be in the region of 5-6%. 20 16

14

Speaking about trade margins, 15 12

In polypropylene (PP), capacity she said surplus capacity and languid There is a potential to maximise 10 10 8

addition is expected to peak in 2024 demand growth would keep margins value and set up dedicated new capaci- Million Tons 5 -7 Million Tons 6 4

at around 7-mtpa and in the next 5-6 depressed for PE and PP for the next ties for these derivatives, even though 0 2 -3

years, the total global PP capacity is two years. This could lead to capa- the volumes are very small and these -5 -2 0

likely to go up by 35-mtpa. city rationalisation and consolidation would have to be co-located with MEG -10 Ethylene Derivatives Defi cit -4 Propylene Derivatives Defi cit

in the industry. “Global olefi ns supply plants. Capacity Demand Ethylene Capacity Demand Propylene

Equivalence

The ongoing PP investment wave is has shifted from tight to long, with new Equivalence

led by Asia (accounting for over 80% capacities coming online. Sharp decline For ethylene derivatives like vinyl benzene production. Indian demand for defi cit for phenol by 2030, while the

of global capacity additions) with a in prices and margins are refl ecting the Mr. Sanjay Sharma acetate monomer (VAM), there has styrene derivatives like ABS, unsatu- co-product acetone’s defi cit is higher at

gigantic share coming from propane underlying excess capacity globally. “The pace of recovery in China will been a signifi cant jump in margins in rated polyester resins (UPR) and close to 400,000-tonnes by 2030.

dehydrogenation (PDH) integrated This situation is set to continue this have a major say in the chemical indus- the last two years for ethylene-vinyl expanded polystyrene (EPS) are

facilities. year and likely into the next year before try margins and prospects. The next 1-2 acetate (EVA) copolymer resulting expected to grow in range of ~6-7%. “Phenol-acetone margins have not

a healthy recovery begins,” Ms. Jain years will be tough for the industry with from growth of solar panels. This has seen sharp dips as other derivatives,

In terms of feedstock, she noted stated. the slow recovery in China. Rationali- made this value chain an attractive In phenol, he said that there is still which makes this an attractive value

that the drop in crude oil processing sation needs to happen to address over- investment opportunity. scope for more capacity additions, even chain for investments in India,” he said.

to match fuel demand has led to lower Over-reliance on China capacity,” he noted. after the recent Haldia Petrochemicals’

volumes of naphtha. With this trend Mr. Sanjay Sharma, Head of Global In propylene oxide, its deriva- announcement. “Indian petrochemical investments

set to play out in the coming decades, Consulting, S&P Global Commodity “Naphtha-based fi rms in Asia are tive, propylene glycol, could witness a will need focus more on steam crack-

naphtha and gas supplies are set to Insights, underlined the fact that over- struggling now and many might go out demand growth of over 7%. Meanwhile After converting the demand for ers. Steam cracker integration is the key

tighten further. “One of the viable reliance on China is hurting the global of business. This slowdown will have in styrene, even as operating rates and epoxy resins, polycarbonates, phenolic where margins are made. Indian steam

options to deal with this feedstock tight- chemical industry as “China is not a an impact on energy transition initia- margins plummet in North-East Asia resins, etc. into phenol equivalents, even crackers are favourably placed on the

ness is COTC (crude oil to chemicals) reliable player given the way they add tives as companies will be focussed (NEA), India can look to take advan- taking into account the Haldia capacity, cost curve compared to NEA counter-

technology,” she said, adding that by capacities or price their products.” more on ensuring survival,” he added. tage of cracker integration and surplus he expected over 200,000-tonnes annual parts,” he said.

SCOPE FOR GROWTH INDUSTRY TRENDS

Opportunities for olefi n derivative investments in India Chinese capacity additions characterise para-xylene

The capacity development initia- dedicated to phenol-acetone produc-

tives in the Indian petrochemicals sec- tion. and benzene markets

tor and specifi c opportunities for olefi n The key trends in the aromatics

derivatives investments were the high- Mr. Rao, however, underlined the industry were discussed by Mr. Vikram

lights of the presentation made by new trend emerging of new steam Sampat, Sr. Vice President, SBU

Mr. Parjanya Rao, Consultant, ICIS. cracker investments being delinked Head – Aromatics, Reliance Indus-

from new refi nery expansions or new tries Ltd.

The next four years would see poly- refi neries. “Except for LPG, India is set

propylene (PP) capacity additions of to be a net exporter for all refi ned pro- In the para-xylene (PX) market,

over 3.5-mtpa, out of which over 90% ducts, while olefi n derivatives will need Chinese investments have led to over-

are linked to refi nery expansions and to be imported. Therefore, the next capacity and operating rate have fallen

propylene from FCC, said Mr. Rao. wave of petrochemicals investments in from 87% to 62% in the fi ve-year

As a result, India could be in a net India could be independent of refi nery period from 2018 to 2023. In these fi ve

balanced position in PP by 2026-2027. Mr. Parjanya Rao expansions,” he noted. years, China added more than 60% to

However, when propylene from FCCs nouncements have been made, the global PX capacity.

is completely extracted, India will have focus still seems to be on high volume Speaking about potential for invest-

to eventually look at more steam crac- polymers like PE, PP or derivatives like ments in olefi n intermediates, Mr. Rao “These new capacities are inte-

kers, he said. monoethylene glycol (MEG), except noted that in ethylene oxide, for deriva- grated with refi neries and many of the

for Haldia Petrochemicals, which has tives like glycols ethers, ethanolamines Chinese PX players are downstream

Even as new steam cracker an- recently announced propylene capacity and ethoxylates, India’s import depen- integrated and are able to maintain Mr. Vikram Sampat

180 Chemical Weekly December 19, 2023 Chemical Weekly December 19, 2023 181

Contents Index to Advertisers Index to Products Advertised