Page 167 - CW E-Magazine (30-1-2024)

P. 167

Special Report Special Report

relatively cheaper to procure; and is piped into the suspension. After Compared with solid LiPF , the

6

Liquid electrolyte solvents & total cost cost of materials PCl is relatively less hazardous some time, LiPF can be generated. yield of liquid LiPF can reach

6

5

6

LiPF salt other: 9 % and is a crystalline solid at normal Although the reaction is also a solid- more than 99%; and

6

conditions. gas reaction, the resulted product The investment per tonne of liquid

production: 19 %

agitation other : 5 % LiPF can dissolve in the organic LiPF6 is lower than that of solid

housing : 9 % 6

electrolyte: 10 % After more than 20 years of contin- solvent, making the reaction inter- products.

anode: 15 % uous improvement and development, face continuously updated, so that

solvents electrolyte separator: 17 %

material: 72 % a process using PC1 , LiCl and anhy- the reaction can go on. Global market

5

+ LiPF 6 drous hydrofl uoric acid (HF) as raw The unreacted LiF and impurities The global LIPF market reached

6

solvents LiPF salt cathode: 44 % materials to prepare LiPF was indus- are insoluble in the solvent and can approximately 50-kt in 2021 and is

6

6

trialized. be easily separated from the LiPF expected to grow at a CAGR of 9.58%

DMC EMC DEC EC LiPF (s) 6

6

Fig. 2: Cost overview of a LIB cell solution. to reach a size of 200-kt till 2035(6). In

CO+O 2 PCl (s) given as: LiC + CoO ⇄ C + PF is obtained by fl uorinating PCl The solvent is then vaporized and 2021, North America accounted for ap-

5

5

6

2

6

5

LiCoO in HF solvent, and the thus-released recovered using appropriate methods, proximately 32% of total demand.

CO 2 2 PF gas was pumped into an anhydrous so high-purity LiPF can be

5

6

methanol ethylene oxide LiF (s) continuous removal of the Manufacture of LiPF 6 HF solution with LiF to produce LiPF . obtained. The automotive industry accounts

6

electrolyte In the 1950s, American scientist The such-prepared LiPF always con- for more than 42% of the market share,

6

Fig. 1: Liquid electrolyte production(2) J.H. Simmons proposed a preparation tains a trace amount of free HF, which As per techno-economic analysis, but industrial energy storage is also a

method for LiPF . He let phosphorous requires complex purifi cation to ensure in a facility with a capacity of making prominent consumer.

6

pentafl uoride (PF ) directly react with the cyclability and safety of the LIBs. 10,000-tpa of LiPF the cost of pro-

6

5

lithium fl uoride (LiF) in a nickel con- This leads to an increase in production duction is around $20 per kg of LiPF , China is the leading producer of

6

tainer to get LiPF : LiF + PF = LiPF . costs. energy consumption is around 30 GWh LIPF . According to Do-Fluoride New

6

5

6

6

per year, and the emission of green- Materials, a leading producer, there are

The reaction went on under high The method has the following dis- house gases in CO -equivalent gases is currently 48 LIPF producers in China.

2

6

temperature and pressure and did not advantages: around 80 tonnes per day(5).

use any solvents. Its main drawback is It uses a large amount of highly cor- Currently, Do-Fluoride and Guang-

that it has a low yield and is diffi cult to rosive anhydrous HF, so requires Compared with solid LiPF , the zhou Tinci Materials Technology Co.,

6

achieve mass production. The reaction the equipment to be highly resistant advantages of liquid LiPF devices are Ltd. dominate the markets; other rele-

6

is a gas-solid reaction. The generated to corrosion; mainly refl ected in two aspects: vant enterprises are Tianji Co., Ltd.,

LiPF can completely cover LiF, pre- Requires cryogenic conditions; In terms of product quality – after Yongtai Technology, Yan’an Bikang,

6

venting the reaction from going on. The reaction has multiple steps and liquefaction, the uniformity of the Shenghua New Materials, Shenzhen

is a long process. product is better, which is more Xinxing, and Morita New Energy

Production of LiPF for LIB elec- conducive to the stability of cus- Materials (3-ktpa capacity).

6

trolytes is constrained by the required While HF is necessary for the pro- tomer product quality and improves

purity (>99.9%) and the type of impuri- duction of LiPF by any method, it has the consistency of cell performance; According to Qidian Lithium, China’s

6

Fig. 3: Charging and discharging of a LIB(4) ties present in the fi nal product. Trace also been used as a solvent. But due to

6

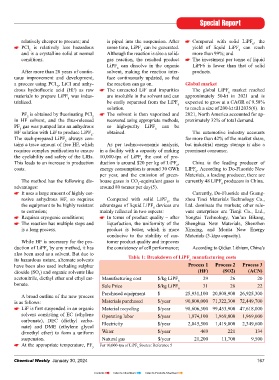

compositions either during calendar year is generally observed in popular amounts of impurities such as moisture, its hazardous nature, alternate solvents Table 1: Breakdown of LiPF manufacturing costs

aging or cycling in LIBs, along with top-brand mobile phones. metal, and free HF are detrimental for have been also used including sulphur Process 1 Process 2 Process 3

formation of deleterious components the life, quality, and safety of the LIB. dioxide (SO ) and organic solvents like (HF) (SO2) (ACN)

2

(e.g., hydrogen fl uoride (HF)) par- The degradation of electrolyte Thus, the raw materials, processing acetonitrile, diethyl ether and ethyl car- Manufacturing cost $/kg LiPF 6 29 26 20

ticularly at elevated temperatures. materials is one of major aging process equipment, and production metho- bonate. Sale Price $/kg LiPF 31 28 22

Consequently, the service lifetime of responsible for capacity and power dology are selected with great caution Purchased equipment $ 6 25,931,100 20,808,900 26,925,300

the state-of-the-art LIBs is usually fading of LIBs, particularly at elevated to avoid any possible contamination. A broad outline of the new process

less than 15 years, which is required temperatures(3). Some of the key considerations in the is as follows: Materials purchased $/year 90,800,000 71,322,300 72,449,700

by EVs to compete with conventional selection of starting materials are: LiF is fi rst suspended in an organic Material recycling $/year 98,606,500 99,453,900 47,618,000

fossil fuel vehicles in terms of cost. In The positive (cathode) electrode LiF and PF are expensive starting solvent consisting of EC (ethylene Operating labor $/year 1,974,100 1,969,000 1,969,000

5

fact, the limited lifetimes of LIBs are half-reaction: CoO + Li + e- ⇄ materials; carbonate), DEC (diethyl carbo- Electricity $/year 2,045,500 1,419,000 2,349,600

2

+

very intuitively sensed by everyone LiCoO 2 PF is a highly toxic gas, making it nate) and DME (ethylene glycol

5

from rapid capacity fading of LIBs The negative (anode) electrode diffi cult and hazardous to store; dimethyl ether) to form a uniform Water $/year 469 221 134

used in portable electronics, wherein half-reaction: LiC ⇄ C + Li + e- Lithium chloride (LiCl) and phos- suspension. Natural gas $/year 21,200 11,700 9,500

6

+

6

at least 20% capacity fading in one The overall reaction thus can be phorus pentachloride (PCl ) are At the appropriate temperature, PF For 10,000-tpa of LiPF Source: Reference 5

5

6

5

166 Chemical Weekly January 30, 2024 Chemical Weekly January 30, 2024 167

Contents Index to Advertisers Index to Products Advertised