Page 139 - CW E-Magazine (15-7-2025)

P. 139

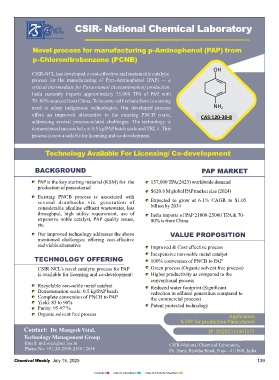

CSIR- National Chemical Laboratory

Novel process for manufacturing p-Aminophenol (PAP) from

p-Chloronitrobenzene (PCNB)

OH

CSIR-NCL has developed a cost-effective and sustainable catalytic

process for the manufacturing of Para-Aminophenol (PAP) — a

critical intermediate for Paracetamol (Acetaminophen) production.

India currently imports approximately 25,000 TPA of PAP, with

70–80% sourced from China. To become self-reliant there is a strong

need to adopt indigenous technologies. Our developed process NH 2

offers an improved alternative to the existing PNCB route, CAS:120-30-8

addressing several process-related challenges. The technology is

demonstrated successfully at 0.5 kg/PAP batch scale and TRL 4. This

process is now available for licensing and co-development.

Technology Available For Licensing/ Co-development

BACKGROUND PAP MARKET

PAP is the key starting material (KSM) for the 157,000 TPA (2023) worldwide demand

production of paracetamol

$620.6 M global PAP market size (2024)

Existing PNCB process is associated with

several drawbacks viz. generation of Expected to grow at 6.1% CAGR to $1.05

considerable alkaline effluent wastewater, less billion by 2034

throughput, high utility requirement, use of India imports of PAP 21000-25000 TPA & 70-

expensive noble catalyst, PAP quality issues, 80% is from China

etc.

Our improved technology addresses the above VALUE PROPOSITION

mentioned challenges; offering cost-effective

andviable alternative Improved & Cost-effective process

Inexpensive non-noble metal catalyst

TECHNOLOGY OFFERING 100% conversion of PNCB to PAP

CSIR-NCL’s novel catalytic process for PAP Green process (Organic solvent free process)

is available for licensing and co-development: Higher productivity as compared to the

conventional process

Recyclable non-noble metal catalyst Reduced water footprint (Significant

Demonstration scale: 0.5 kg/PAP batch reduction in effluent generation compared to

Complete conversion of PNCB to PAP the commercial process)

Yield: 85 to 90%

Purity: 95-97 % Patent protected technology

Organic solvent free process Application

KSM for production Paracetamol

Contact: Dr. Mangesh Vetal, IP: IN202311061153

Technology Management Group

Email: md.vetal@ncl.res.in CSIR-National Chemical Laboratory,

Phone No: +91-20-2590-2138 / 2638 Dr. Homi Bhabha Road, Pune - 411008, India.

Chemical Weekly July 15, 2025 139

Contents Index to Advertisers Index to Products Advertised