Page 172 - CW E-Magazine (30-7-2024)

P. 172

Special Report Special Report

Plug-and-produce modular automation: the catalyst needs of different applications by add-

HMI Process ing new or altered functionality. Proto-

Control

for chemical plants to embrace IoT and Industry 4.0 typing or testing of new processes is

Archive MTP History similarly diffi cult. Requiring hours or

or decades, large-scale automa- supply chains, driven by factors such as AXEL HALLER days of programming and testing slows

the pace of innovation and hinders the

tion systems have been essential political tension, terrorism, and natural Global Industry Business Manager Diagnoses Controller

Ffor production line control, but disasters. This situation has presented for Chemicals and Life Sciences ability to bring new or improved pro-

ducts to market in short timescales that

their lack of fl exibility often hinders opportunities to innovate and improve ABB customers increasingly demand.

chemical plants from quickly adapting stability, addressing dramatic price

to changing market demands. The fl uctuations and unpredictable supply meanwhile grappling with an ongoing Scaling up can be a similarly slow

paper explores how standardised ‘plug- patterns, and ultimately enhancing the skills shortage, triggered by the retire- and costly process, often requiring

and-produce’ modular automation availability of both fi nished products ment of many experienced engineers signifi cant investment in new infra-

solutions can enable producers to fully and raw materials. who are leaving the industry, taking structure and extended periods of plant

leverage the advantages of the Internet decades of know-how and practical downtime to accommodate major up-

of Things (IoT) and Industry 4.0. Driving sustainability and agility in expertise with them. In common with

the chemical industry several other industrial sectors, this is grades or expansion. From a safety and

The chemical industry faces some Refl ecting the global pressure on accompanied by a shortage of young risk management perspective, mean-

tough challenges against a rapidly organisations to commit to greater cir- engineering talent with the skills, rele- while, it is often more diffi cult to quickly

identify, isolate, and remediate safety

changing technological, economic, and cularity and sustainability across the vant experience and enthusiasm to risks in large conventional automation

geopolitical landscape. supply chain, chemical companies are pursue career opportunities in process Source: ABB

now demonstrating their compliance control and automation. As a result of demand. Manufacturing plants can all plant operation – is conventionally systems. Routine maintenance or repair

Competition has never been keener, with stringent regulations in areas such this skills drain and a shrinking work- struggle to ramp production up or down overseen by a large-scale automation of conventional systems can also call

with customers demanding higher qua- as carbon emissions reduction, waste force, chemical producers – in common quickly and adapt lines to deliver new system. These large, monolithic sys- for shutting down a production line or

lity, more customised products, shorter management, and effi cient resource with many other large industrial organi- products. In particular, it is diffi cult for tems are effectively bespoke solutions entire plant, impacting on productivity

delivery times and lower prices. In a utilisation. In tandem, industrial organi- sations – are now increasingly reliant plants to maintain effi ciency and profi t- that have been designed and imple- and profi tability.

period of ongoing uncertainty follow- sations are aligning with advanced on hiring in EPC (Engineering, Pro- ability as customer demand grows for mented to meet a specifi c production

ing the global pandemic and ongoing regulatory and safety standards, neces- curement, Construction) contractors to small batch sizes, sometimes as small need. Their inherent design, however, The move to modular automation

confl ict in several world regions, vola- sitating investment in cutting-edge manage tasks that would formerly have as one unit. This market trend toward means that the conventional automa- To address these challenges, chemi-

tility in the cost of energy and raw mate- equipment, procedures, and training been resourced in-house. ultra-customisation is typifi ed in fi ne tion systems that underpin them often cal producers are now seeking a more

rials puts further pressure on organi- to protect staff and ensure compliance and specialty chemical production, as lack the fl exibility to adapt quickly to agile, effi cient and future-proof alter-

sations’ cost management, operating with current legislation. Adapting to market demands well as the pharmaceutical industry, new or changed production require- native to decades-old plant automation

margins and overall profi tability. Against this backdrop, one of the which is increasingly characterised by ments. methodologies as a central part of their

Navigating skills gaps and workforce biggest challenges faced by the chemi- short-run production, runs driven by digitalisation strategies.

These uncertainties have highligh- evolution cal industry is synchronising produc- the rise of personalised medicines. It is diffi cult to customise large-

ted the need for greater resilience in The process control industry is tion capacity to fast-evolving customer scale automation systems to meet the The concept of ‘modularisation’ is

Collectively, these pressures have

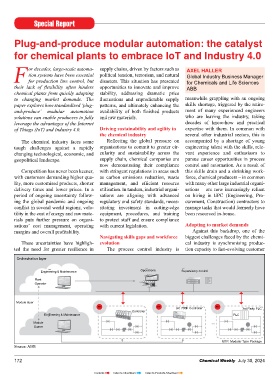

Orchestration layer exposed the limitations of conventional

process automation systems that have

Engineering & Maintenance Operations Supervisory control enabled and managed production line

Plant control for decades. Today’s large-scale

Operator chemical plants typically prioritise the

effi cient production of specifi c dedica-

ted products. As such they are optimised

Module layer for rapid, high-yield production with

MTP MTP AC 700F Controller MTP 3rd Party PLC large batch sizes in the range of tens

Controller

Engineering & Maintenance PLC of thousands of tonnes or more, where

Module product changes are infrequent during

Owner the life of the plant.

In this environment, control over a

MTP: Modular Type Package

Source: ABB large number of processes – and over- Source: ABB

172 Chemical Weekly July 30, 2024 Chemical Weekly July 30, 2024 173

Contents Index to Advertisers Index to Products Advertised