Page 137 - CW E-Magazine (31-10-2023)

P. 137

Top Stories PRODUCTS AVAILABLE FOR SALE now available in india

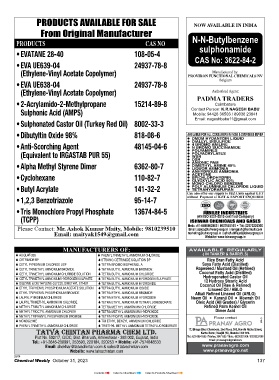

From Original Manufacturer

METAL TREATMENT CHEMICALS Products cas no N-N-Butylbenzene

DFPCL’s PICKBRITE range helping enhance performance • EVATANE 28-40 108-05-4 sulphonamide

of pickling process in SS production • EVA UE639-04 24937-78-8 CAS No: 3622-84-2

(Ethylene-Vinyl Acetate Copolymer) Manufactured by:

The use of stainless steel (SS) complexity of the pickling process, and higher chemical consumption per Proviron functional cHeMicals nv

is widespread not just in our house- which is based on the requirement of tonne of SS. • EVA UE638-04 24937-78-8 Belgium

holds, but also extends to industrial the end-product and the unique pro- (Ethylene-Vinyl Acetate Copolymer) Authorised Agent:

use, transportation, construction and cess followed by steel manufacturers. Trials performed with PICKBRITE PadMa traders

the like. solution was a proven success in pick- • 2-Acrylamido-2-Methylpropane 15214-89-8 Coimbatore

As the pickling solution cannot ling effi cacy, chemical consumption, Contact Person: K.R.NAGESH BABU

While SS production is rather be standardised, PICKBRITE is a quality of fi nished metal, pickling Sulphonic Acid (AMPS) Mobile: 94426 36503 / 89036 23641

common, its many challenges are customised solution unique to every throughputs, effl uent generation and Email: nageshbabu11@gmail.com

hardly highlighted. During the pro- manufacturer and is formulated after more, with several observed benefi ts • Sulphonated Castor Oil (Turkey Red Oil) 8002-33-3

cess of manufacturing SS, oxides are careful inspection of the manufac- including: >20% increase in through- • Dibutyltin Oxide 98% 818-08-6 AVAILABLE FOR ALL CONSUMERS IN INDIA & OVERSEAS BUYER

formed on the surface of SS, parti- turing process. Furthermore, the custo- put from bath; >50% reduction in l DMDM HYDANTOIN LIQUID

cularly at the time of hot processing and mised solution also optimises the pro- HF consumption; >20% reduction in • Anti-Scorching Agent 48145-04-6 l DIALLYL DISULFIDE

l 4 BROMO ANILINE

annealing. As a consequence, there is cess parameters and ensures higher nitric acid consumption; >35% re- l N BROMO SUCCINAMIDE

l POLYAMINES

inadequate corrosion resistance. operational effi ciency without any duction in lime consumption; >20% (Equivalent to IRGASTAB PUR 55) l POLYACRYLATES

l WSR

signifi cant process changes. reduction in effl uent generation; and l DSR

l ANIONIC PAM

The preferred solution to tackle >35% reduction in sludge generation. • Alpha Methyl Styrene Dimer 6362-80-7 l DIMETHYL AMINE 40%

l LIQUOR AMMONIA

this is to treat the SS surface with Proven success • Cyclohexane 110-82-7 l ANHYDROUS AMMONIA

l ACETONE

l EPICHLOROHYDRIN

chemicals such as strong acids – a “DFPCL’s PICKBRITE pickling Apart from the above, PICKBRITE l GLYOXYLIC ACID 50%

l MONO CHLORO BENZENE

treatment known as pickling. Most solution doesn’t just improve the sur- also reduced the bath preparation • Butyl Acrylate 141-32-2 l POLY ALUMINIUM CHLORIDE LIQUID

l TETRAHYDRAFURAN

often, mixtures of nitric acid and face quality of SS, but also enhances time and increased bath throughput. can also offer our supply to seZ units against lut

hydrofl uoric acid (HF) are used to the effi cacy of the process. That’s not Sludge removal from the pickling • 1,2,3 Benzotriazole 95-14-7 without Payment of iGst & eXPort enQuires

remove the thin layer of metal/oxide all – it also reduces the overall cost bath tank was also much faster, while

scale from the surface of SS. In some of the treatment and extends the life sludge handling was reduced. Fur- • Tris Monochloro Propyl Phosphate 13674-84-5 JUBILEE INDUSTRIES

instances, potassium permanganate, of the pickling bath solution,” a state- thermore, freshwater consumption (TCPP) (AN ISO 9001-2015 certified Company)

ISHWAR CHEMICALS AND GASES

sodium hydroxide, and other chemi- ment by DFPCL said. for bath preparation and lime solution Mob: +91-8888862805 / 8007655155 w Tel: 02572220300

cals are needed, based on the grade of preparation also reduced by 33%. Please Contact: Mr. ashok Kumar Maity, Mobile: 9810239510 Email: sales@ishwargroup.in / ramgas1@hotmail.com

the metal. To corroborate the benefi ts, the email: maityak1549@gmail.com marketing@ishwargroup.in / ashish.chhajed@ishwargroup.in

Website: www.ishwargroup.in

company provided the several bene- Lastly, this solution helped with a

While there is no dearth of pick- fi ts that accrued at a leading manufac- 5-10% increase in monthly pickling Manufacturers of:

ling solutions available, Deepak turer of SS products having integra- capacity and offered better safety by S AliquAt-336 S PheNyl trimethyl AmmoNium chloride AvAilABlE REGUlARly

( iN TANKER & BARRElS)

Fertilisers and Petrochemicals Corpo- ted manufacturing facilities, starting reducing the consumption and hand- S cetrimide BP S stroNG cetrimide solutioN BP Rice Bran Fatty Acid

Soya Fatty Acid (Distilled)

ration Ltd. (DFPCL) is offering its from a melting shop to fi nished SS ling of highly hazardous HF and S cetyl PyridiNium chloride usP S tetrA Bromo BisPheNol A Rapeseed / Mustard Oil (Refined)

PICKBRITE range of products, which products in different forms like wires, nitric acid. It also helped with S cetyl trimethyl AmmoNium Bromide S tetrA Butyl AmmoNium Bromide Coconut Fatty Acid (Distilled)

S cetyl trimethyl AmmoNium chloride solutioN

S tetrA Butyl AmmoNium chloride

stand out as an effective pickling wire rods, welding wires, fl anges, additional cost saving, since time was S cetyl trimethyl AmmoNium hydroGeN sulPhAte S tetrA Butyl AmmoNium hydroGeN sulPhAte Hydrogenated Castor Oil

12 Hydroxy Stearic Acid

solution for SS alloys. This specia- fasteners and bright bars, which are saved in bath preparation that helped S diGlyme & diethyleNe Glycol dimethyl ether S tetrA Butyl AmmoNium hydroXide Coconut Oil (Raw & Refined)

lised solution is uniquely formulated supplied to automotive, defence, with higher production. There was S ethyl triPheNyl PhosPhoNium AcetAte solutioN S tetrA Butyl AmmoNium iodide Linseed Oil / HBLO

Alkali Refined Linseed Oil (ARLO)

and designed to reduce hydrofl uoric mining and many more industries. also some cost saving observed due S ethyl triPheNyl PhosPhoNium Bromide S tetrA ethyl AmmoNium Bromide Neem Oil l Karanji Oil l Mowrah Oil

S lAuryl PyridiNium chloride

S tetrA ethyl AmmoNium hydroXide

acid consumption in the SS pickling It was facing several challenges during to power consumption and reduced S lAuryl trimethyl AmmoNium chloride S tetrA ethyl AmmoNium tetrAFluoroBorAte Oleic Acid (All Grades) / Glycerin

process. This, in, turn reduces the the pickling process – from handling manpower. Additionally with opti- S methyl triButyl AmmoNium chloride S tetrA methyl AmmoNium chloride Refined Palm Kernel Oil

Dimer Acid

effl uent generation and load on the of hazardous chemicals like HF and mised pickling, PICKBRITE has S methyl trioctyl AmmoNium chloride S tetrA methyl AmmoNium hydroXide

S tetrA ProPyl AmmoNium hydroXide

S methyl triPheNyl PhosPhoNium Bromide

effl uent treatment plant (ETP). nitric acid, to additional burden on potential to retain higher weight of S moNoGlyme S tri ethyl BeNZyl AmmoNium chloride Please contact (Ad.-1)

the wastewater treatment plant, and the fi nished products. “Similarly, S PheNyl trimethyl AmmoNium chloride S triethyl methyl AmmoNium tetrAFluoroBorAte

According to the company, the excess pickling acid sludge gene- benefi ts have been observed at a few TaTva ChinTan Pharma Chem lTd. 17, Bhagu Bhai Chambers, 2nd Floor, 363, Narshi Natha Street,

Katha Bazar, Masjid (W), Mumbai 400 009.

success of the PICKBRITE range of ration. Moreover, their process was other SS product manufacturers as Plot No. 502/17, Gidc, dist. Bharuch, Ankleshwar - 393 002, Gujarat, india Tel.: 022-66541585 / Telefax: 23471585 * Mob.: 09220271904 / 09223237366

Email: pranavagro@gmail.com

products lies in its ability to accept the experiencing lesser pickling bath life well,” the DFPCL statement added. Tel.: +91-2646-238991, 253593, 220184, 220253 w Mobile: +91-7574848533 www.pranavagro.com

Email: shekhar@tatvachintan.com & sales@tatvachintan.com

Website: www.tatvachintan.com www.pranavagro.net

29/14

136 Chemical Weekly October 31, 2023 Chemical Weekly October 31, 2023 137

Contents Index to Advertisers Index to Products Advertised