Page 165 - CW E-Magazine (13-5-2025)

P. 165

Special Report

self-fl ush the crystalline salt and assure separation retention time (+40%). This dissolution is an attractive pro-

the stability of this passive system. work demonstrates the capability of the cess. (ACS Sustainable Chem. Eng.,

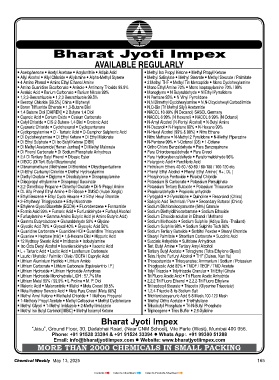

There is zero discharge and can stably title strategy. (Angew. Chem. Intl. Ed., 2024; DOI: 10.1021/acssuschemeng. Bharat Jyoti Impex

desalinate 70 gm per/litre NaCl solution 2024; DOI: 10.1002/anie.202416884). 4C0480).

with water yield of 1.33 kg per sq. m. AVAILABLE REGULARLY

per hr. and salt collection of about Rare-earth elements (REE) Design and hydrodynamics Acetophenone Acetyl Acetone Acrylonitrile Adipic Acid Methyl Iso Propyl Ketone Methyl Propyl Ketone

0.34 kg per sq. m. per hr. at 60°C. This recovery from electronic waste of a novel multidowncomer Allyl Alcohol Allyl Chloride Allylamine Alpha-Methyl Styrene Methyl Salicylate Methyl Stearate Methyl Stearate / Palmitate

is adoptable for large-scale commercial bubble-breaking (MDBB) tray 4 Amino Phenol Amino Ethyl Ethanol Amine 2 Methyl THF Methyl Tin Mercaptide Mono Cyclohexylamine

production. (Chem. Eng. Jl., 2024, 498, E. Sanchez Moran et al have referred Amino Guanidine Bicarbonate Anisole Antimony Trioxide 99.8% Mono Ethyl Amine 70% Mono Isopropylamine 70% / 99%

15 Oct., 155095; DOI: 10.1016/j.cej. to REEs as possessing unique magnetic, W. Wang et al have come out with a Azelaic Acid Barium Carbonate Barium Nitrate 99% Monoglyme N Butyraldehyde N Ethyl Pyrrolidone

1,2,3-Benzotriazole 1,2,3 Benzotriazole 99.5%

N Pentane 95% N Vinyl Pyrrolidone

2024.155095). luminescent, and catalytic properties and novel MDBB which is based on the Benzoyl Chloride [99.5%] China Biphenyl N,N Dimethyl Cyclohexylamine N,N-Dicyclohexyl Carbodiimide

are thus seen as key resources for di- “droplet bubble-breaking” method to Boron Trifluoride Etherate 1,3-Butane Diol N,O-Bis (Tri Methyl Silyl) Acetamide

Mechanochemical “Cage-On- verse applications, such as in electronic enhance the mass transfer process. 1,4 Butane Diol [DAIREN] 2 Butyne 1,4 Diol NACOL 10-99% (N Decanol) SASOL Germany

MOF” strategy for enhancing devices, industrial components, mili- Caproic Acid Cerium Oxide Cesium Carbonate NACOL 6 99% (N Hexanol) NACOL 8 99% (N Octanol)

N-Amyl Alcohol (N-Pentyl Alcohol) N-Butyl Amine

Cetyl Chloride CIS-2-Butene-1,4-Diol Crotonic Acid

gas adsorption and separation tary defence equipment, etc. Electronic Cyanuric Chloride Cyclohexanol Cyclopentanone N-Decanol N-Heptane 99% N-Hexane 99%

through aperture matching (e-) waste constitutes a rich source of Cyclopropylamine D - Tartaric Acid D-Camphor Sulphonic Acid N-Hexyl Alcohol (99% & 98%) Nitro Ethane

REEs. These authors have carried out Di Cyclohexylamine Di Ethyl Ketone Di Ethyl Malonate Nitro Methane N-Methyl 2 Pyrolidone N-Methyl Piperazine

Y. Liang et al have worked on getting a technoeconomic analysis (TEA) and Di Ethyl Sulphate Di Iso Butyl Ketone [DIBK] N-Pentane 99% 1-Octanol (C8) 1-Octene

Di Methyl Acetamide [Henan Junhua] Di Methyl Malonate

Ortho Chloro Benzaldehyde Para Benzoquinone

more out of adsorptive separations reduce environmental impact of land Di Phenyl Carbonate Di Sodium Phosphate Anhydrous Para Chlorobenzaldehyde Para Cresol

and post-modifi cation of porous mate- fi lling. Thus the recovery of didymium 2,4 Di Tertiary Butyl Phenol Dibasic Ester Para Hydroxybenzaldehyde Paraformaldehyde 96%

rials with molecular modulators is of oxide (DO) recovery from hard drive DIBOC (Di Tert. Butyl Dicarbonate) Pelargonic Acid Perchloric Acid

importance. These authors have the shreds through acid-free dissolution Dibromomethane (Methylene Di Bromide) Dicyclopentadiene Petroleum Ethers 40-60 / 60-80 / 80-100 / 100-120 etc.

Phenyl Ethyl Alcohol Phenyl Ethyl Amine [ R+ ; DL ]

Di-Ethyl Carbamyl Chloride Diethyl Hydroxylamine

mechanochemical “Cage-On-MOF” recycling is covered. An analysis Hydrodynamic parameters were studied Diethyl Oxalate Diglyme Diisobutylene Diisopropylamine Phosphorous Pentoxide Pivaloyl Chloride

strategy, utilising porous coordination shows that 342.42 tonnes of hard drive with respect to gas-liquid fl ow pattern, Diisopropyl ethylamine Diisopropyl Succinate Potassium Bi Carbonate Potassium Persulphate

cages (PCCs). Only the combinations shreds per year allows recovery of gas holding, dry pressure drop, clear 2,2-Dimethoxy Propane Dimethyl Oxalate Di-N-Propyl Amine Potassium Tertiary Butoxide Potassium Thioacetate

of PCCs and MOFs with closely DO at 2.53 tonnes whose estimated liquid height, residual pressure drop, DL Alfa Phenyl Ethyl Amine D-Ribose DMSO (Hubei Xingfa) Propionaldehyde Propionic anhydride

matched aperture sizes exhibited en- price is $130/kg. The minimum sell- and wet pressure drop. CO absorption Ethyl Benzene Ethyl Cyclo Hexane 2 Ethyl Hexyl Bromide Pyrogallol 2-Pyrrolidone Quinoline Resorcinol (China)

Salicylic Acid Technical / Pure Secondary Butanol (China)

2-Ethylhexyl Thioglycolate Ethyl Nicotinate

2

hanced gas adsorption and separation ing price, with improvements, can experiment were done for comparing Ethylene Glycol Diacetate (EGDA) Fluorobenzene Formamide Sodium Dichloroisocyanurate (56%) Granule

performance. MOF-808@PCC-4 exhi- reach $173/kg. A comparison of the traditional sieve trays, multidowncomer Formic Acid 99% Fumaric Acid Furfuraldehyde Furfuryl Alcohol Sodium Diethyldithiocarbamate Sodium Ethoxide

bited a significantly increased C H hydrometallurgical and electrometal- trays and MDBB and MDBB showed Furfurylamine Gamma Amino Butyric Acid (4 Amino Butyric Acid) Sodium Ethoxide solution in Ethanol / Methanol

2

2

uptake (+64%) and a longer CO /C H lurgical process indicates that acid-free improved performance. (Ind. Eng. Gamma Butyrolactone Glutaraldehyde 50% Glycine Sodium Methoxide Sodium Sulphite (Aditya Birla -Thailand)

2 2 2 Glycolic Acid 70% Glyoxal 40% Glyoxylic Acid 50% Sodium Sulphite 98% Sodium Sulphite Tech 90%

Chem. Res., 2024; DOI: 10.10214/acs. Guanidine Carbonate Guanidine HCl Guanidine Thiocyanate Sodium Tertiary Butoxide Sorbitol Powder Stearyl Bromide

iecr.4C03090). Guanine Heptane [mix] 1,6-Hexane Diol Hippuric Acid Stearyl Palmitate Strontium Carbonate Succinic Acid

12 Hydroxy Stearic Acid Imidazole Isobutylamine Succinic Anhydride Sulfolane Anhydrous

Regeneration of LiFePO from Iso Octa Decyl Alcohol Isovaleraldehyde Itaconic Acid Tert. Butyl Amine Tertiary Amyl Alcohol

L + Tartaric Acid Lactic Acid Lanthanum Carbonate

Tertiary Butyl Acetate Tetraglyme (Tetra Ethylene Glycol)

spent materials 4 Lauric / Myristic / Palmitic / Oleic / DCFA / Caprylic Acid Tetra Hydro Furfuryl Alcohol THF (Dairen, Nan Ya)

Lithium Aluminium Hydride Lithium Amide Thioacetamide Thiocyanates: Ammonium / Sodium / Potassium

S. Song et al have emphasized the Lithium Carbonate Lithium Carbonate [Equivalent to I.P.] Thioglycolic Acid 80% TMOF / TEOF / TMO Acetate

importance of recycling and regene- Lithium Hydroxide Lithium Hydroxide Anhydrous Tolyl Triazole Tolyltriazole Granular Tri Ethyl Citrate

ration of LiFePO for sustainable Lithium Hydroxide Monohydrate LIOH : 57.7% Min Tri Fluoro Acetic Acid Tri Fluoro Acetic Anhydride

2,2,2 Tri Fluoro Ethanol 2,2,2-Tri Fluoro Ethylene

Lithium Metal 99% / 99.9% L-Proline M. P. Diol

4

development and even environmental Malonic Acid Malononitrile Maltol Meta Cresol 99.5% Tri Isodecyl Stearate Triacetin (Glycerine Triacetate)

protection. The infl uence of Al impurity Meta Hydroxy Benzoic Acid Meta Para Cresol [Meta 60%] 1,2,4-Triazole & its Sodium Salt

is discussed with respect to electro- Methyl Amyl Ketone Methallyl Chloride 1 Methoxy Propanol Trichloroisocyanuric Acid 5-8 Mesh,100-120 Mesh

chemical performance of regenerated 1-Methoxy Propyl Acetate Methyl Cellosolve Methyl Cyclohexane Triethyl Ortho Acetate Triethylsilane

Methyl Glycol 1-Methyl Imidazole 2-Methyl Imidazole

Triisobutyl Phosphate Tri-N-Butyl Phosphate

LiFePO . Leaching was done with Methyl Iso Butyl Carbinol [MIBC] Methyl Isoamyl Ketone Triphosgene Triss Buffer 2,6-Xylidine

4

150 gm/litre of H SO ; Al removal

4

2

and control was achieved by simply Bharat Jyoti Impex

adjusting the pH value. The recovered “Jasu”, Ground Floor, 30, Dadabhai Road, (Near CNM School), Vile Parle (West), Mumbai 400 056.

product exhibits excellent performance. Phone: +91 91528 33394 & +91 91524 33394 Whats App:. +91 99300 51288

(ChemSusChem., 2024; DOI: 10.1002/ Email: info@bharatjyotiimpex.com Website: www.bharatjyotiimpex.com

cssc.202401432). More than 2000 CheMiCals in sMall PaCking

164 Chemical Weekly May 13, 2025 Chemical Weekly May 13, 2025 165

Contents Index to Advertisers Index to Products Advertised