Page 175 - CW E-Magazine (12-3-2024)

P. 175

Special Report

panies) enterprise, which is represented International Business Machines Cor- uids including oils, diesel, naphtha,

by Shuye Environmental Technology poration (IBM) (Armonk, NY, USA), and monomers as well as syngas, char,

(Shantou, China). DuPont Teijin Films (Tokyo, Japan), to waxes. Depending on the obtained

and Dow (Midland, MI, USA). products these can be utilised as renew-

Enzymolysis able feedstocks for the production of

An alternative path represents Pyrolysis new polymers.

enzymolysis, a technology based on bio- With pyrolysis, a thermochemical

chemical processes utilising different recycling process is available that With 40,000-tpa, the second-largest

kinds of biocatalysts to depolymerise a converts or depolymerises mixed capacity found in the report is realised

polymer into its building units. Being in plastic wastes (mainly polyolefins) and with pyrolysis. The majority of the 80

an early development phase, this tech- biomass into liquids, solids, and gases identified technology providers are

nology is available only at lab-scale. in presence of heat and absence of located in Europe (42 providers) followed

Currently, only one enzymolysis tech- oxygen. Obtained products range from by North America (21 providers), Rest

nology provider was identified, which for instance different fractions of liq- of the world (11 providers), China (four

is a small enterprise located in Europe.

Solvolysis

The solvent-based solvolysis

describes a chemical process based on

depolymerisation, which can be realised

with different solvents. This process

breaks down polymers (mainly PET)

into their building units (e.g. mono-

mers, dimers, oligomers). After break-

down, the building units need to be

cleaned from the other plastic compo-

nents (e.g. additives, pigments, fillers,

non-targeted polymers). After cleaning,

the building units are polymerised to

synthesise new polymers.

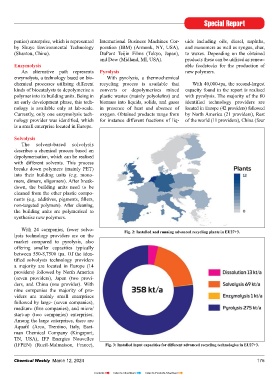

With 24 companies, fewer solvo- Fig. 2: Installed and running advanced recycling plants in EU27+3.

lysis technology providers are on the

market compared to pyrolysis, also

offering smaller capacities typically

between 550-8,7500 tpa. Of the iden-

tified solvolysis technology providers

a majority are located in Europe (14

providers) followed by North America

(seven providers), Japan (two provi-

ders, and China (one provider). With

nine companies the majority of pro-

viders are mainly small enterprises

followed by large- (seven companies),

medium- (five companies), and micro/

start-up (two companies) enterprises.

Among the large enterprises, there are

Aquafil (Arco, Trentino, Italy, East-

man Chemical Company (Kingsport,

TN, USA), IFP Energies Nouvelles

(IFPEN) (Rueil-Malmaison, France), Fig. 3: Installed input capacities for different advanced recycling technologies in EU27+3.

Chemical Weekly March 12, 2024 175

Contents Index to Advertisers Index to Products Advertised