Page 165 - CW E-Magazine (8-7-2025)

P. 165

Special Report Special Report

and methyl imidazolium trifl uoroacetate 2,600-ppm to below 50-ppm in the

were found to be optimal IL. Process fi nal permeate, even though two similar

simulations were done. This strategy of solutes were involved. (Org. Proc. Res.

Dev., 2024; DOI: 10.1021/acs.oprd.

By solving a formulated 4C00333).

MINLP problem based on CAILD

Ordered 2D RUB-15

nanosheets with high loading

in mixed matrix membranes

Solvent design (MMMs) for H /CO

separation 2 2

[The separation of H /CO continues to

2

2

attract a lot of attention and this column

has covered some papers.]

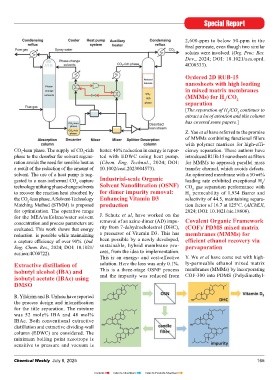

areas) have further improved via “sepa- selective CMS membrane with respect Z. Yao et al have referred to the promise

ration cogeneration” where most of the to both a cost and energy standpoint. of MMMs combining functional fi llers

electrical energy supplied to the HP This strategy has potential compared to with polymer matrices for high-effi-

compressor is recovered as steam or Parex process, which is adsorptive sepa- CO -lean phase. The supply of CO -rich better. 40% reduction in energy is repor- ciency separation. These authors have

2

2

process heat at/or higher than the reboiler ration. (Ind. Eng. Chem. Res., 2024; DOI: phase to the desorber for solvent regene- ted with EDWC using heat pump. introduced RUB-15 nanosheets as fi lters

temperature. Simulations indicate 79% 10.1021/acs.iecr.4C021803). Process design ration avoids the need for sensible heat as (Chem. Eng. Technol., 2024; DOI: for MMMs to approach parallel mass

to nearly 90% of the supplied electrical 0.8 a result of the reduction of the amount of 10.1002/ceat.2023004573). transfer channel, which avoids defects.

energy can be recovered as usable steam/ Ionic Liquid (IL)-assisted solvent. The use of a heat pump is sug- An optimized membrane with a 50 wt%

process heat. This strategy appears to be Extractive Distillation (ED) gested to a near-isothermal CO capture Industrial-scale Organic loading rate exhibited exceptional H /

2

2

attractive. (Ind. Eng. Chem. Res., 2024; for ethylene/ethane separation 0.4 Byproduct(s) technology utilising phase-change solvents Solvent Nanofi ltration (OSNF) CO gas separation performance with

2

DOI: 10.1021/acsiecr.4C03190). [This column has covered many papers 0.2 IL solvent to recover the reaction heat absorbed by for dimer impurity removal: H permeability of 1,934 Barrer and

2

Other utilities

on ethylene-ethane (and propylene-pro- GWP (kg CO 2 eq/kg product) 0.6 the CO -lean phase. A Solvent-Technology Enhancing Vitamin D3 selectivity of 44.5, maintaining separa-

Techno-economic analysis pane) separation, which is done through 0.0 Steam Matching Method (STMM) is proposed production tion factor of 16.7 at 125°C. (AIChEJl,

2

of a carbon molecular sieve cryogenic distillation, which entails high -0.2 for optimisation. The operative range 2024; DOI: 10.1021/aic.18606).

(CMS)-based xylene isomer capex and energy consumptions. Several -0.4 for the MEA/sulfolane/water solvent J. Schutz et al, have worked on the

purifi cation process papers based on adsorptive separation -0.6 Conventional separation [C 1Py][TFA]-based [C 1Im][TFA]-based concentration and process parameters are removal of an azine-dimer (AD) impu- Covalent Organic Framework

seperation process

seperation process

have been covered in this column.] process Process evaluation evaluated. This work shows that energy rity from 7-dehydrocholestrol (DHC), (COF)/ PDMS mixed matrix

C.J. Roos et al have worked on this subject reduction is possible while maintaining a precursor of Vitamin D3. This has membranes (MMMs) for

as high purity p-xylene is required for Y. Lei et al have come out with a novel ED leads to total annual cost reductions a capture effi ciency of over 90%. (Ind. been possible by a newly developed, effi cient ethanol recovery via

multimillion ton per annum purifi ed tere- strategy of separation by ED using IL. of 46.5% and 69.8%, respectively. Energy Eng. Chem. Res., 2024; DOI: 10.1021/ sustainable, hybrid membrane pro- pervaporation

phthalic acid (PTA). These authors have These authors made use of computer-aided consumption is decreased by 41.6% acs.iecr.4C00722). cess, from the idea to implementation.

come out with a techno-economic-analysis IL design (CAILD) for screening of sol- and 42.1%, respectively. (Ind. Eng. This is an energy- and cost-effective Y. Wu et al have come out with high-

of commercial attractiveness of p-xylene vents. Methyl pyridinium trifl uoroacetate Chem. Res., 2024; DOI: 10.1021/acs. Extractive distillation of solution. Here the loss was only 0.1%. ly-permeable ethanol mixed matrix

iecr.4C02483).

isobutyl alcohol (IBA) and This is a three-stage OSNF process membranes (MMMs) by incorporating

Evaluation of near-isothermal isobutyl acetate (IBAc) using and the impurity was reduced from COF-300 into PDMS (Polydimethyl-

phase-change CO capture DMSO

2

technology with heat pump

[This column has covered several papers R. Yildirim and B. Unlusu have reported

in the recent past for CO removal with the process design and intensifi cation

2

respect to new amines, biphasic system, for the title separation. The mixture

catalysing desorption including using was 52 mole% IBA and 48 mol%

ultrasound.] IBAc. Both conventional extractive

distillation and extractive dividing-wall

D. Chang et al have referred to the absorp- column (EDWC) are considered. The

tion of CO with phase-change solvents, minimum boiling point azeotrope is

2

which results in a CO -rich phase and a sensitive to pressure and vacuum is

2

164 Chemical Weekly July 8, 2025 Chemical Weekly July 8, 2025 165

Contents Index to Advertisers Index to Products Advertised